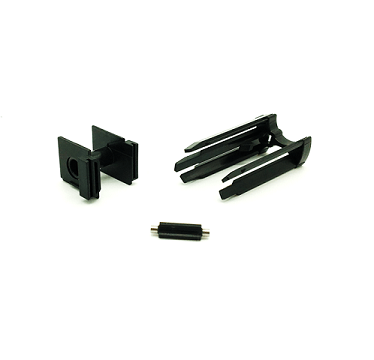

Medical Devices

With 30 years of market experience we are leading manufacturing partner to the top medical device OEMs.

Markets

Contract Manufacturer

with 30 years of experience.

Certifications

Certified manufacturer for the

Healthcare, Aerospace, and defense industries.

Global Locations

USA – China – Hong Kong

Fully owned manufacturing

facility in China.

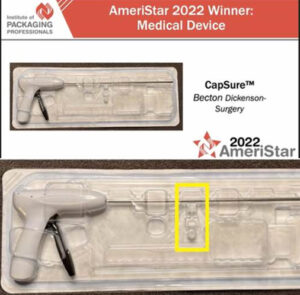

AmeriStar 2022 Medical Device Package Winner

Pioneer Plastics Inc proudly presents our collaboration with Becton Dickenson Surgery and SEE Forming LLC to win the Ameristar 2022 medical device award.

This new innovative packaging design reduces the cost of packaging, as well as, better supports the device’s security.

Pioneer Plastics Inc strives to take ideas into reality using innovation and technology to take products from prototypes to production.

Pioneering your ideas with innovation and technology to take products from prototyping to production.

Global Technical And Manufacturing Solutions. Request a quote.

DFM, Mould Flow

Rapid Prototyping

CN & US Project Mgmt

Project Mgmt

Tool Designers

Full scale molding

Integrated ERP (EPICOR)

Best molding equipment

Thermoset molding

Clean room molding

Expedited transfer tooling

ISO-13485

IATF 16949

ISO-9001

About

At Pioneer we provide innovative solutions for the medical device, defense, automotive and industrial industries since 1985. Improving New Product Development lead times through rapid prototype, DFM, mold flow and China tooling capability. Driving customer satisfaction through thermoplastic & thermoset molding, assembly, global manufacturing, quality, KANBAN, and competitive Total Cost Of Ownership.We prioritize our customer relations to a high standard, aiming to exceed customer satisfaction. Supporting our customer on various fronts: design tweaks, alternative resin suggestions, and ways to save money and time. Learn more by contacting us at info@pioneerplastic.com

-Thermoplastics, Thermoset Molding, Assembly and Decorating.

-New product Development

-Global Manufacturing (US & CN)

-Medical Device, Defense, Autonomous & Industrial Applications

What has been said

Their work is of such outstanding quality, they are clearly experts in their field.

For any manufacturing task, Factory are by far the most innovative in the industry.

The creativity we encountered throughout was simply world class.

There is incredible peace of mind knowing that you’re in the hands of professionals.

“Trusted Full Product Life Cycle Partner”

Global Locations

3660 Dodd Road

Eagan, MN, USA 55123

USA

Group Tool Inc

510 S Spencer St

Lexington, IL, USA 61753

China

Pioneer Plastech

102,Building 31,

West Industrial Zone B4,

Tantou Community,

Songgang Town,

Shenzhen China 518105

Hong Kong

Pioneer Plastech Limited

194-200 Lockhart Rd, HK