BACKGROUND:

A longtime customer in the medical device industry produced a subassembly from a Pioneer Plastic’s molded component, which was being assembled at a semiconductor subcontractor’s facility. An FDA registered medical-grade adhesive was sourced by the subcontractor’s design team, which is used to retain a magnet inside the molded component’s pocket.

SITUATION:

The sub-assembly used a specific grade of adhesive, which was a registered BOM component that was included in the FDA design submission. The product was identified in the field with magnets that had egressed the molded component pocket. $750 K in finished goods inventory was placed on hold and quarantined until a solution could be identified. The adhesive could not be replaced, without resubmitting the product to the FDA for approval. The challenge was to create a robust solution to retain the magnet in the molded component pocket; without altering the existing design of the molded component, magnet, or adhesive. Ideally, this solution could be applied to improve the $750 K of finished goods inventory.

SOLUTION:

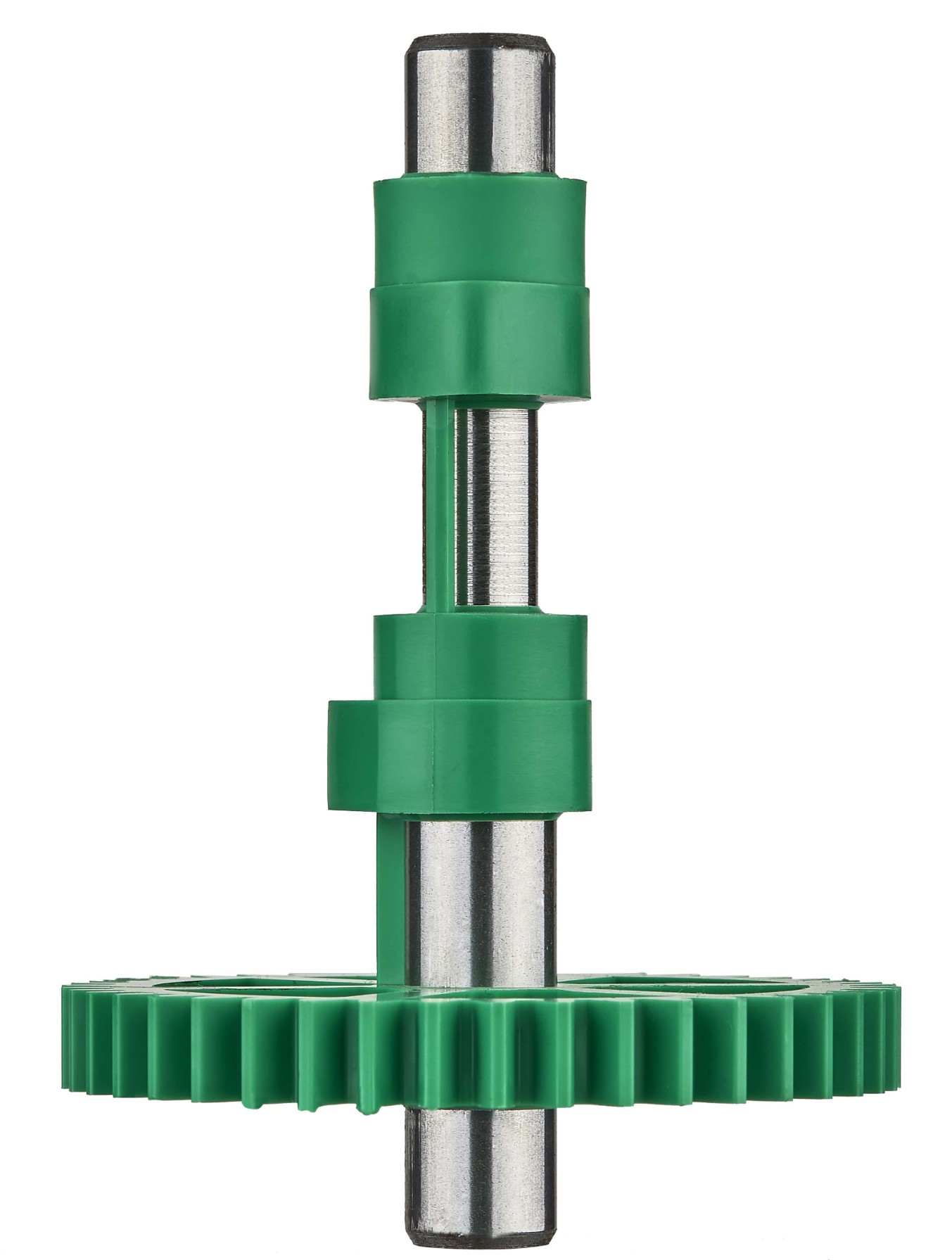

Pioneer’s engineering team analyzed the design of the molded component pocket and variations in the magnet geometry. A DOE was performed to evaluate a variety of discreetly located thermal forming operations, which could be added to the existing assembly process to eliminate the possibility of magnet egress. The secured magnets could no longer be removed from the molded component without mechanically stripping the molded material away. Custom automation was designed and fabricated at Pioneer Plastics to replace the existing manual magnet loading process, and thermally form material around the magnet.

FULL RESULT INCLUDED:

The FDA was notified and the product design and function were not altered The adhesive could continue to be included in the improved process for FDA compliance$750K of finished goods could undergo an additional value-added process Pioneer’s Automation design & build improved:

Magnet loading

Magnet orientation

In-process verification

100% certainty of installed magnet retention

Our customers quickly resumed producing products, and delivery to hospitals.