Welcome to

Group Tool Inc.

About Group Tool

Our Core Capabilities

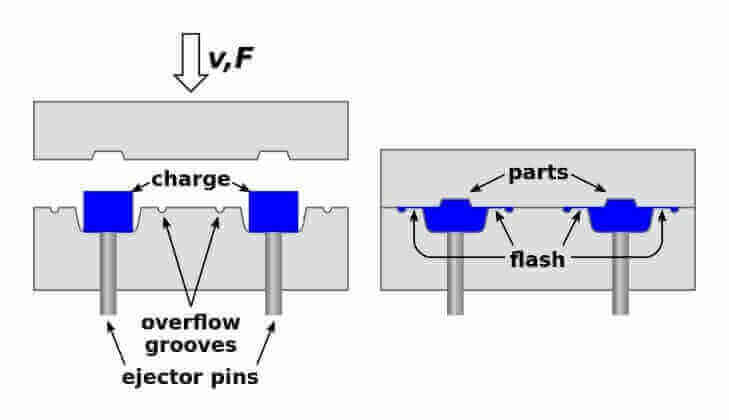

Injection Molding and Compression Molding

- Expertise in both thermoset and thermoplastic molding

- High-volume production of complex and mission-critical parts

- Specialized knowledge in BMC, SMC, and a wide range of engineered thermoplastic resins including glass-filled, flame-retardant, and high-heat materials

- Ability to support everything from small prototype runs to sustained, large-scale production

Material Expertise

- Extensive background with thermoset resins such as Durez, IDI, and Sumitomo Bakelite

- Proven performance with engineered thermoplastics such as nylons, polycarbonates, PBT, and high-performance blends

- Experience with high-temperature, flame-retardant, and arc-resistant compounds for demanding applications

- Resin qualification, material testing, and supplier partnerships to ensure reliability

Value-Added Services

- Prototyping and sample runs for new product development

- Secondary operations including deflashing, sanding, and assembly

- Quality control with rigorous dimensional verification and traceability

Thermoset Injection and Compression Molding

Pioneer Plastics has over 34 years of experience in injection and compression molding resins that are used in Automotive and Industrial applications. Thermoset resins offer unique physical properties that are highly desired in high temperature and specific applications. Our technical and operations team is familiar with a wide variety of thermoset resins ranging from 200T to 500T. Broad range of press tonnage options allows us to accommodate parts that weigh less than a few grams to parts that are over few kilograms in weight. Over the years we have developed strategic partnerships with thermoset resin OE’s and custom compounders which allows us to offer tailored solutions for your applications.

- Bulk Molding Compound (BMC).

- Phenolics.

- Sheet Molding Compound (SMC).

- Thermoset Polyester, Vinyl Ester.

- Epoxy.

- Diallyl Phthalate (DAP).

Industries We Serve

Electrical distribution and switchgear

Oil and gas including frac ball technology

Power generation and industrial equipment

Automotive and heavy equipment applications

Our Commitment

“Trusted Full Product Life Cycle Partner”

Global Locations

3660 Dodd Road

Eagan, MN, USA 55123

510 S Spencer St

Lexington, IL, USA 61753

China

Pioneer Plastech

No.5. the 2nd Jingye Rd Yanchuan Community Yanluo Street Bao’an District Shenzhen, CHINA PC 518105